LONGINES ULTRA-QUARTZ 6512 1970

Longines was a part of the Quartz project led by CEH and some very rare "QuartzChron" Beta21 watches were made for Longines. This however must have been costly (as joining CEH was far from cheap) so Longines created their own inhouse 6512 calibre making a one of a kind and only Cybernetic watch in the World! The "Ultra-Quartz" is very very different from other inventions of that era although the idea was based on the Accutron concept - thus it is also considered to be a member of the Hummer family. The crown is smartly fitted on the back additionally underlining the precision of the movement which looks like an unfinished yet amazing prototype. Check this manual / bulletin and watch out for mid 70's Ultra-Quartz with ESA9181!

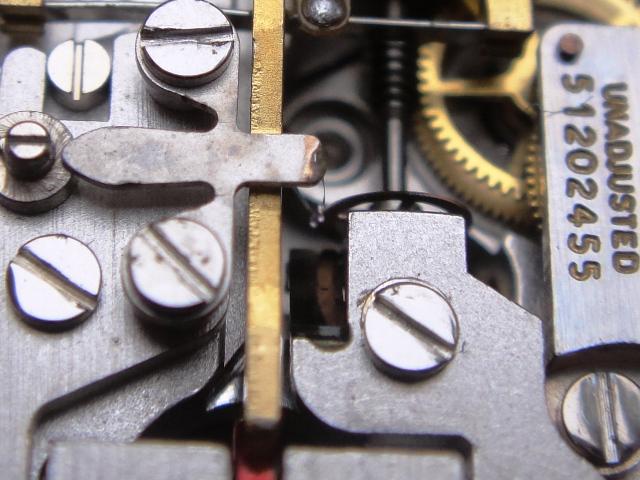

The motor module with Accutron type pawl and index fingers consists of a torsion bar with coil and counter-weight on both ends that vibrates at 170Hz. On top of that there is an electronic maze manually assembled with 14 transistors, 19 resistors, 7 capacitors and a quartz crystal vibrating at 9350Hz. This fact was even used for marketing purposes to place their product above the Beta with "only" 8192Hz :)) Instead of spending a fortune on the microchip that was used in the Beta21 the Longines developed their own "circuitry" that did even more. This brain does not only divide the high quartz frequency into smaller portions transmitted to the motor but it cybernetically "communicates" with both default frequencies (170Hz and 9350Hz) and performs corrective actions (if needed) by modifying the output impulses in the motor.

The 4.3kOhm motor coil was probably a quick-fix and was simply glued to the torsion bar. This solution did not prove reliable thus finding a working watch is a real miracle. The coil is totally exposed and vibrates in between two permanent magnets - the least amount of shock during wear will cause the coil to move and scratch its surface in the small magnetic gap. To make this even worse after so many years the epoxy resin (plastic) that holds the coil starts to decay and crack and I have personally experienced a fatal accident when a properly functioning coil broke from the torsion bar after installing a battery. Hint: check the resin and apply a new very thin preventive film for another 50 years of proper functionality - this will not affect timekeeping.

Also improper handling and sequence during disassembly is a possible source of failure of the motor. Both ultra-thin wires (ends) of the coil are soldered to the bottom side of the torsion bar assembly and covered with epoxy - one end in the very middle (just slightly below the pawl finger) and the other end is hanging loose and is soldered onto the tip of the small substrate (with one trace) that provides current to the coil. When removing the motor module and unscrewing the corresponding gilded screw I suggest holding this plate (just in case) as it should be permanenty glued onto the torsion bar assembly and must not be removed. Note! In a similar fashion to Omega also Longines came up with repair modules for their solid gold Ultra-Quartz watches. Check out THIS official Longines workaround using a mid-70's ESA calibre!

Also improper handling and sequence during disassembly is a possible source of failure of the motor. Both ultra-thin wires (ends) of the coil are soldered to the bottom side of the torsion bar assembly and covered with epoxy - one end in the very middle (just slightly below the pawl finger) and the other end is hanging loose and is soldered onto the tip of the small substrate (with one trace) that provides current to the coil. When removing the motor module and unscrewing the corresponding gilded screw I suggest holding this plate (just in case) as it should be permanenty glued onto the torsion bar assembly and must not be removed. Note! In a similar fashion to Omega also Longines came up with repair modules for their solid gold Ultra-Quartz watches. Check out THIS official Longines workaround using a mid-70's ESA calibre!

Keywords: longines ultra-quartz, 6512

Market value: 250-1500$ (condition, box)